EV Motor Stator Assembly Line with Hairpin Tech

Every motor has a core component - the stator.

In the past 10 years, global EV brands have researched different winding technologies.

Since 2017, the leading technology has been "hairpin winding".

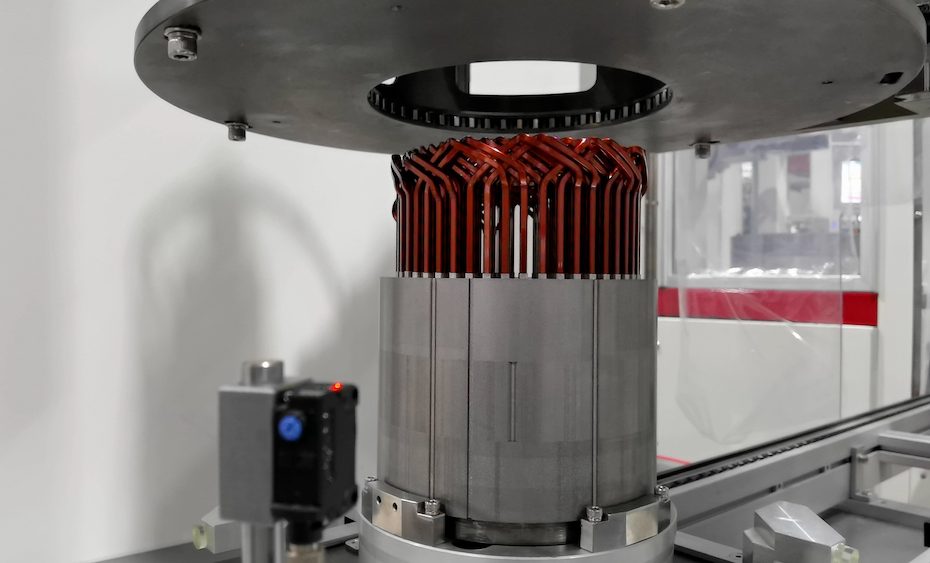

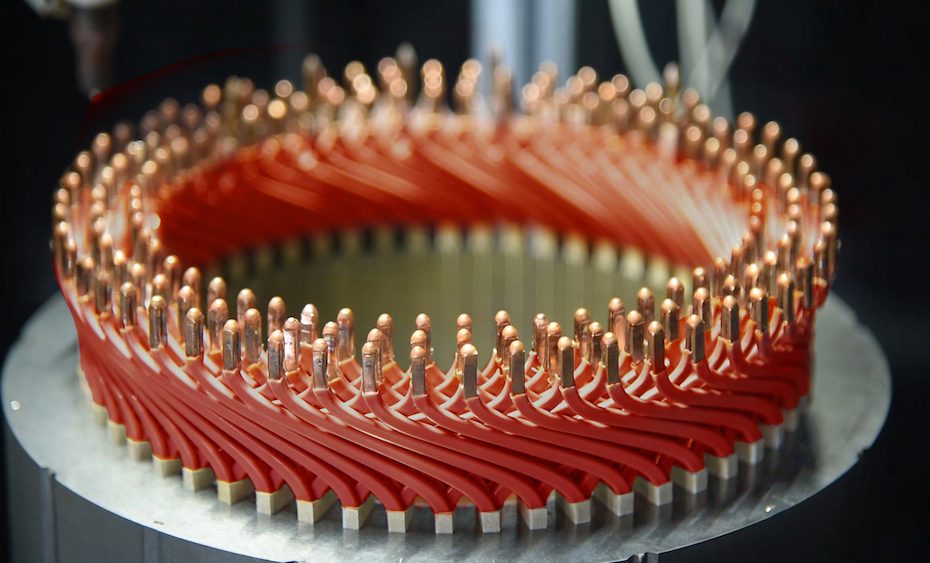

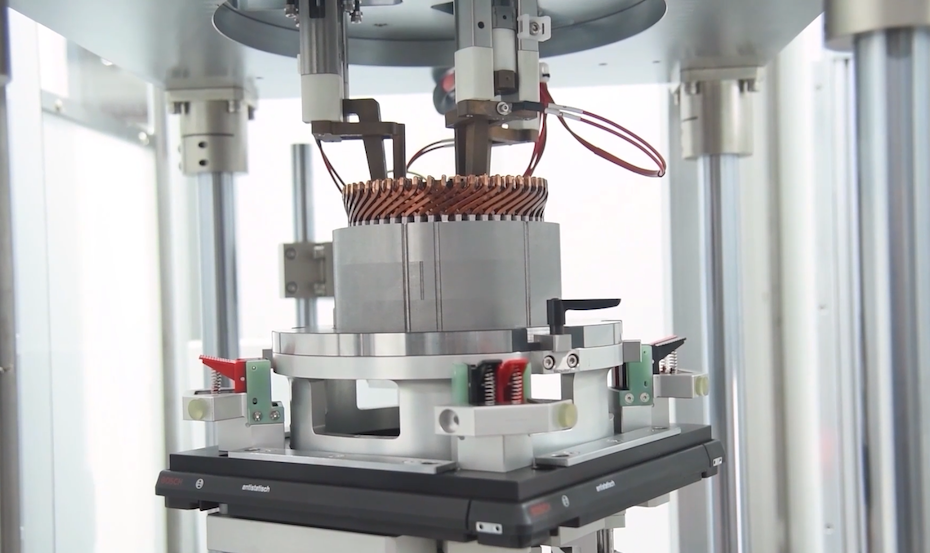

This consists of several U-formed pins formed into a basket, inserted into the stator, and then processed on the other end with each two pin ends welded together. The result is a complete winding cycle.

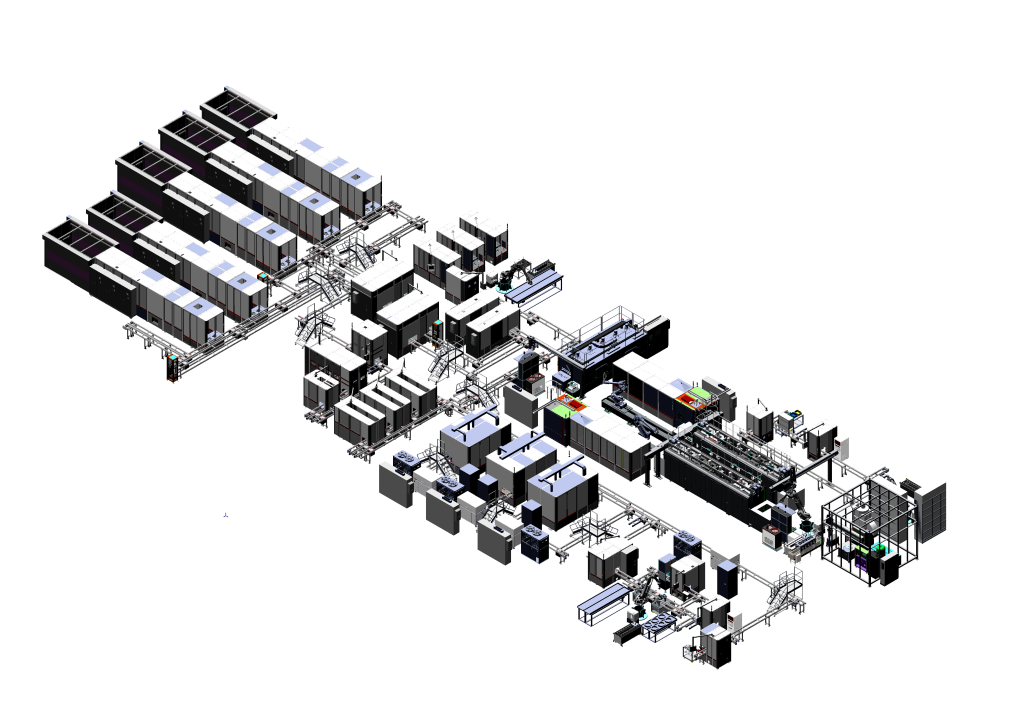

JULI Automation has provided more than 30 hairpin winding assembly lines in the past 5 years, most of which are highly automated.

In 2018, JULI Automation provided China's first automated EV motor stator line with hairpin technology.

The complete winding process involves 10 single-process steps:

1. Paper insertion

2. Basket Setup

3. Basket Insertion

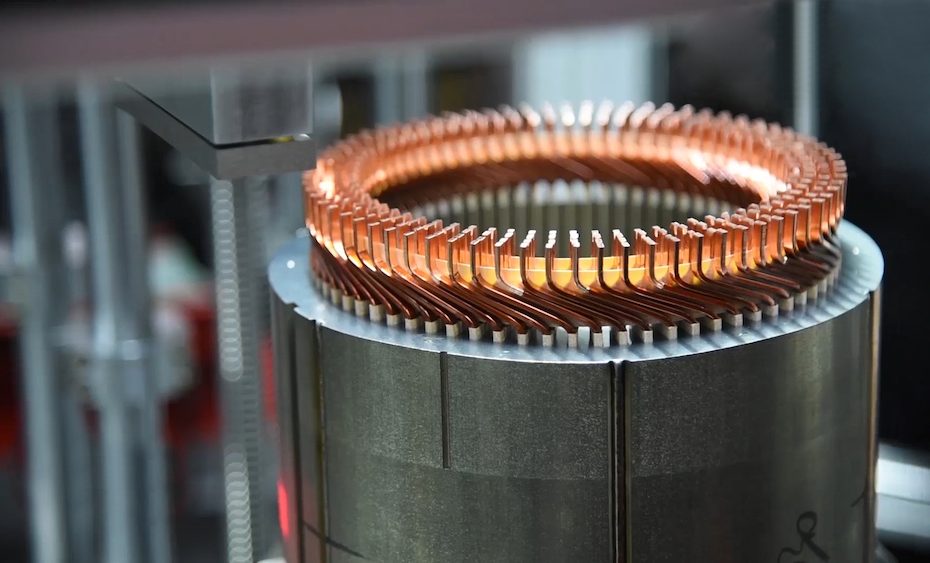

4. Widening

5. Twisting

6. Trimming

7. Welding

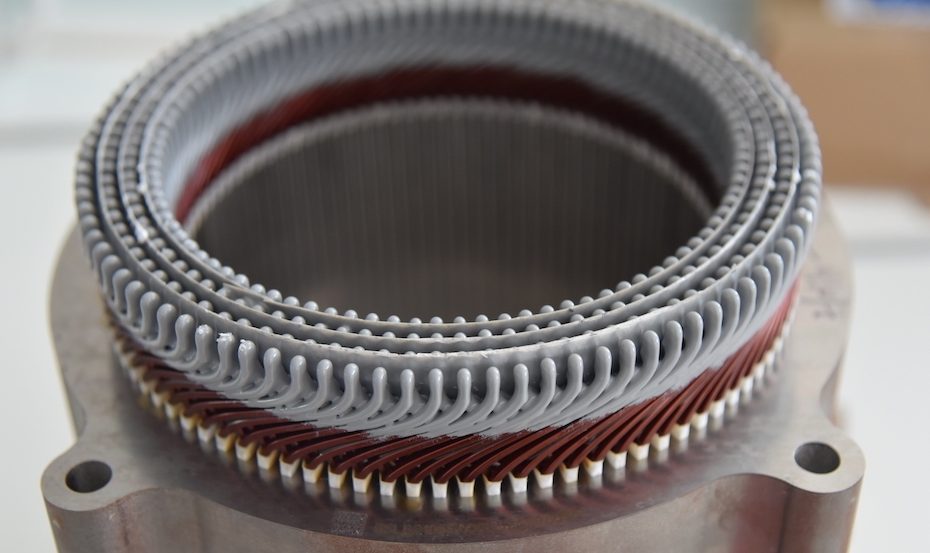

8. Impregnation

9. Powder Coating

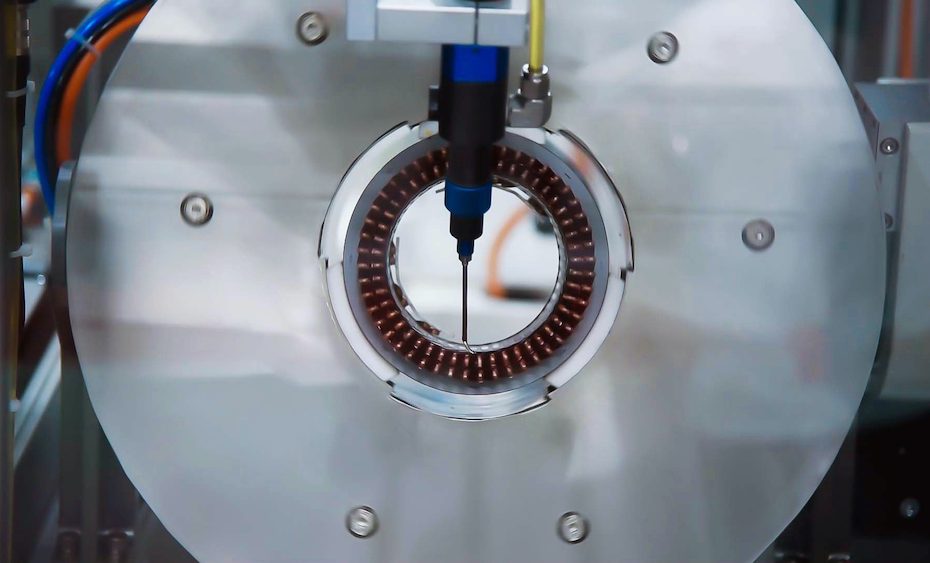

10. Electrical performance test

These process steps have been developed over several years and are constantly improved.

If you choose an automated EV stator assembly line with hairpin technology, you benefit from our decades of R&D and project management.